Our customer Standic has built the first phase of a new tank terminal for the storage of chemicals in 2020/2021. Within this project, 79 storage tanks were built including all necessary infrastructure such as a Jetty, truck transfer station and railway freight station.

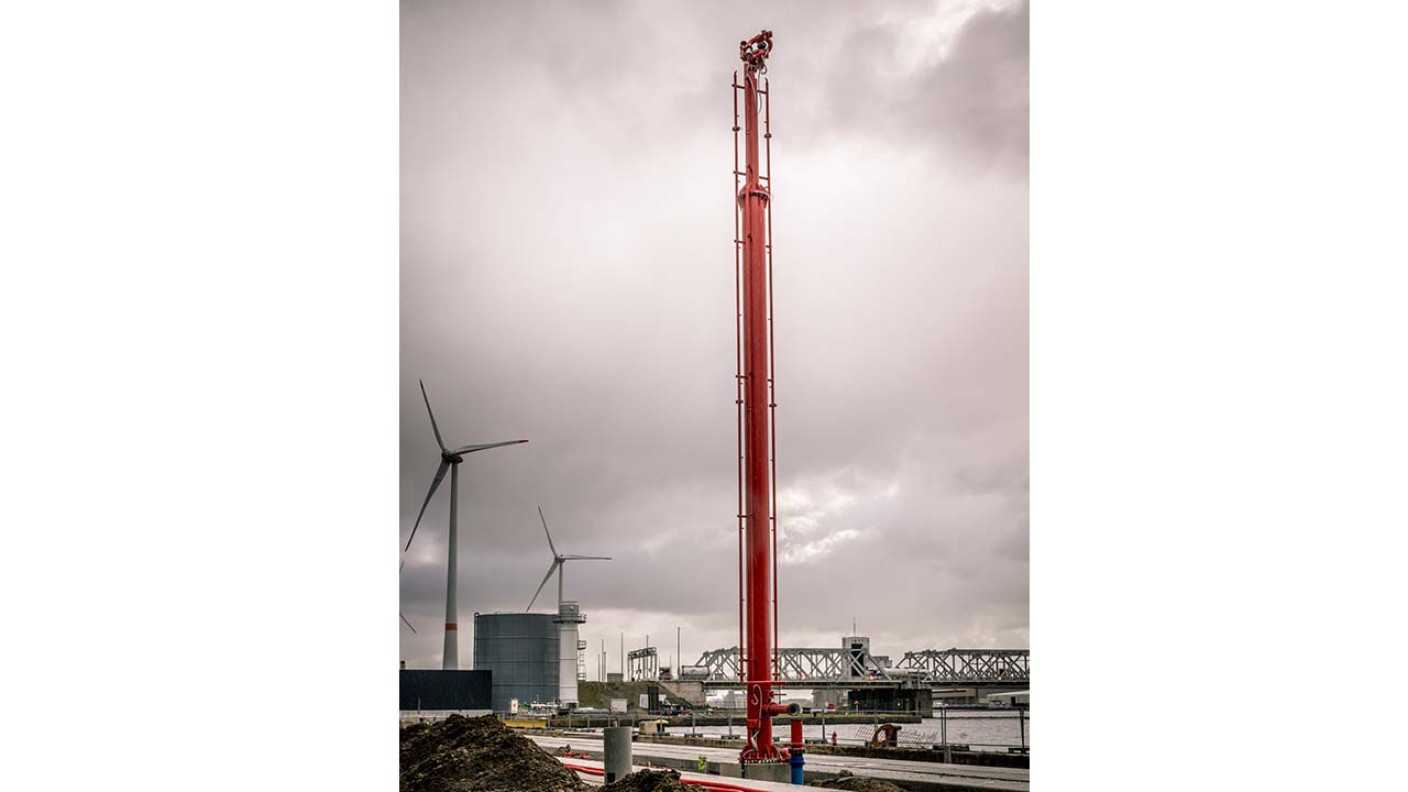

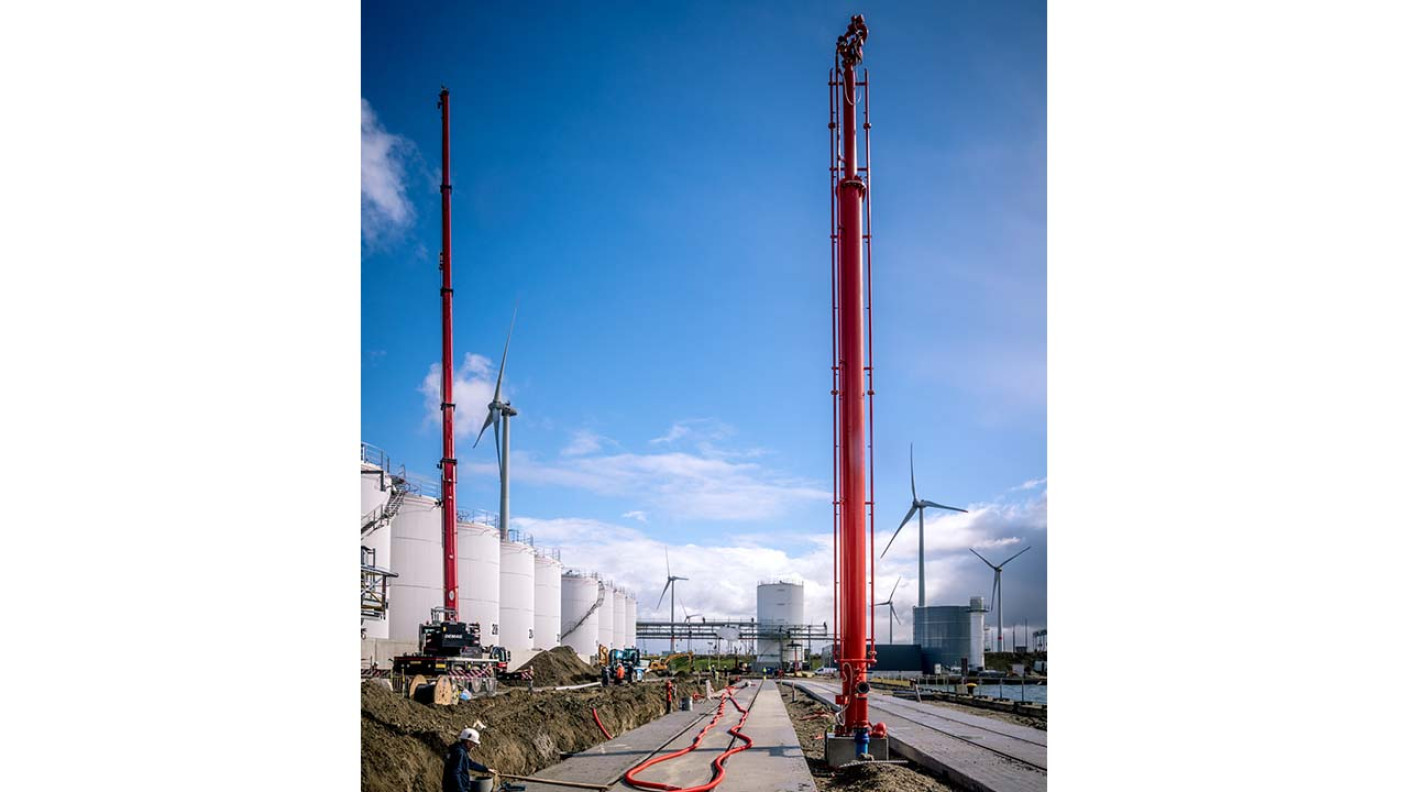

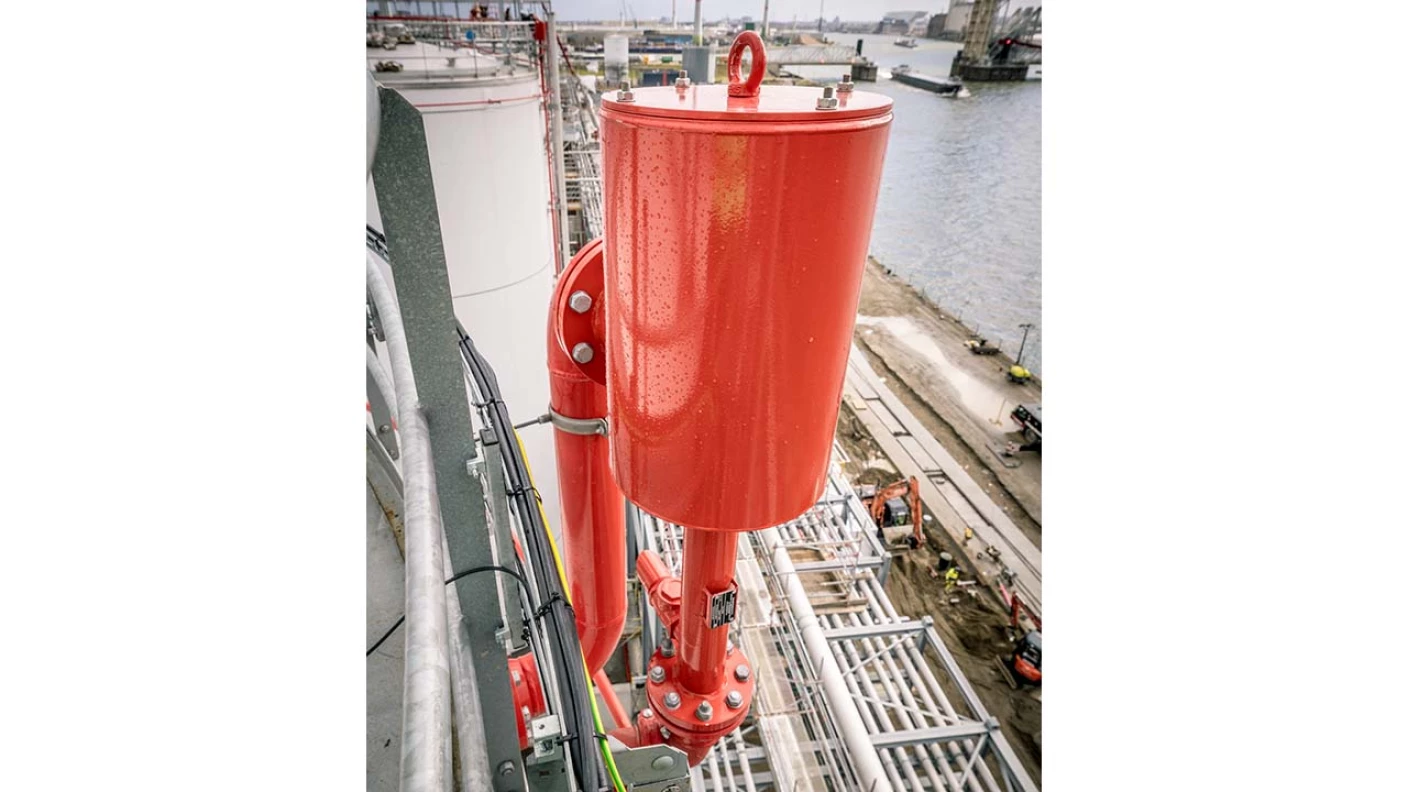

Somati Systems engineered and built the fire extinguishing systems and the flame and gas detection systems. The current and upcoming EU regulations regarding restrictions on PFAS containing extinguishing foam concentrate were taken into account when designing the fire-fighting foam installations. A fluorine-free extinguishing foam concentrate has been used, which is pumped from one central pressure tank via underground pipes to various manifolds on the site.

Environmentally friendly testing with the foamtronic

A FoamTronic proportioner has been installed to mix the extinguishing foam. A major advantage of this proportioner is the functionality of the foam mixing installations can be tested without actually needing to mix water and foam.

Distribution to various locations at the terminal

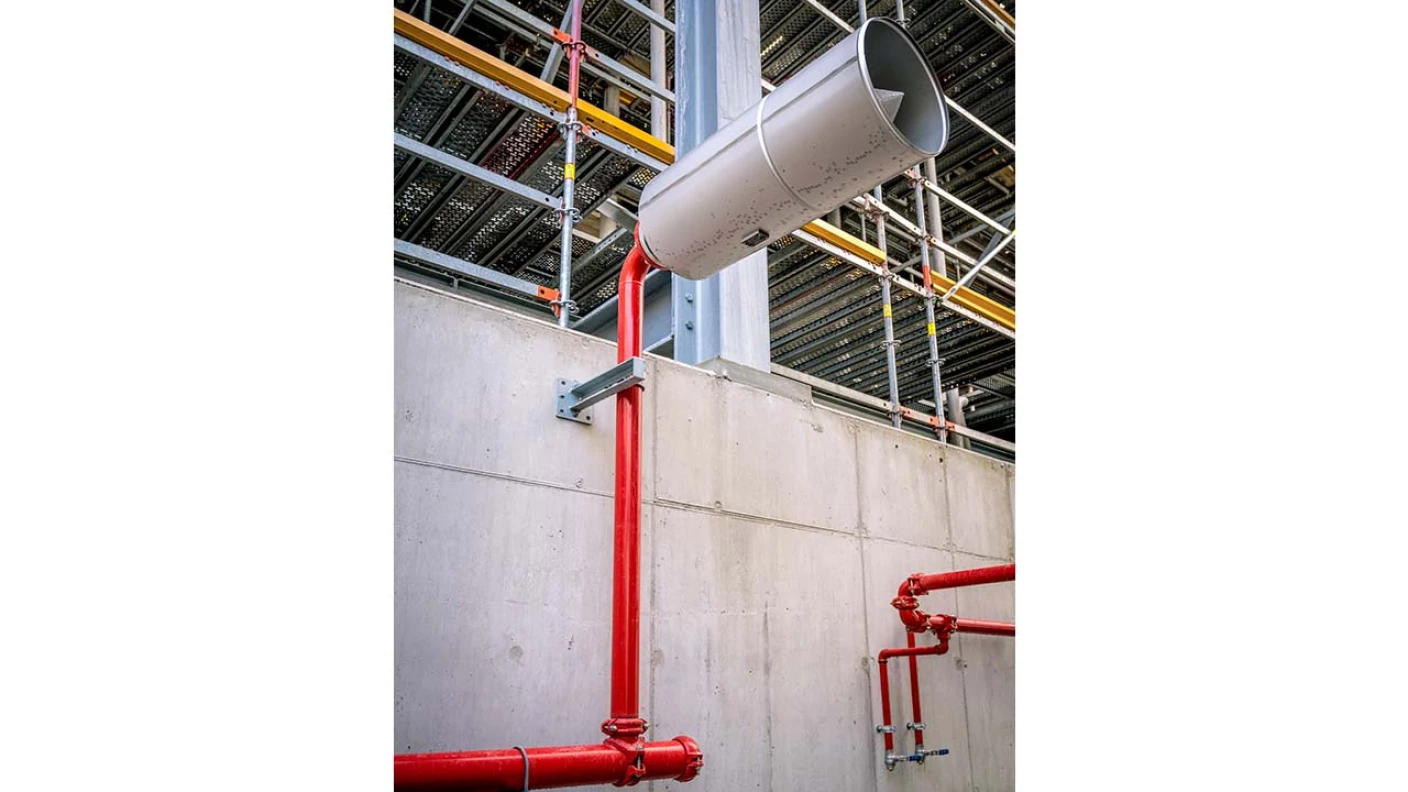

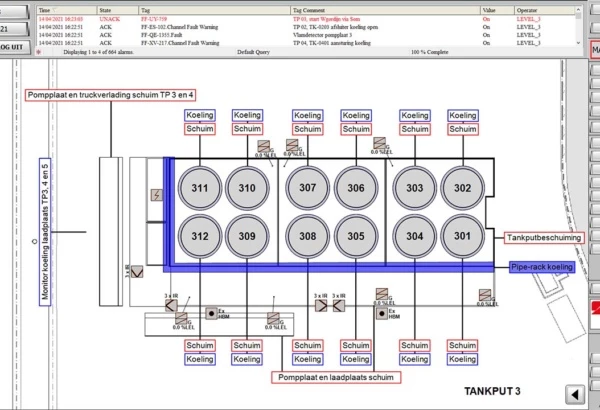

The pipes run from these manifolds for cooling and foaming the storage tanks, foaming the tank pits, cooling and/or foaming the product pump stations and the truck transfer stations.

Complete visualization system

The entire installation is displayed on a visualization system intended for this purpose, from which the extinguishing installations can be operated. In addition, a connection has been made with the process visualization system, the extinguishing installations can also be controlled via this system. A Det-Tronics FM approved F&G system was used in this project, this system has also been demonstrably tested for monitoring and controlling the extinguishing installations.

It is necessary to be able to cool and to extinguish with foam in the event of a liquid fire at the truck transfer stations. It was a challenge to come up with a qualitative solution. Since we work with fluorine-free extinguishing foam concentrate, it is important to obtain good foaming. In addition, there was no steel structure above the truck transfer stations, so we needed a nozzle that had to be directional and suitable for cooling and extinguishing with foam. For this application, Saval has developed the F3 nozzle where the solution meets all requirements.